- Home

- About Jim

- Jim Writes…

- The Newest Jim Weiss Recordings

- Recordings: All Jim Weiss Recordings

- A Quick Look at Jim Weiss Recordings by Title & Suggested Age Level

- Recordings: Timeline by Historic Era

- Recordings: Curriculum Guideline

- Recordings: Virtues & Values

- Book An In-Person Jim Weiss Presentation

- Book A Live, Jim Weiss Zoom/Webinar for Your Organization

- Fantastic & Free Jim Weiss Webinars, Videos and Podcasts

- Jim Weiss Workshop Handout(s)

- Jim Weiss’s Travel Calendar

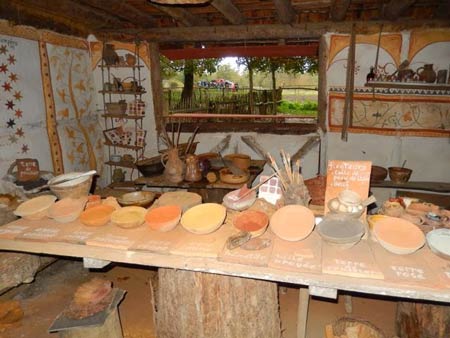

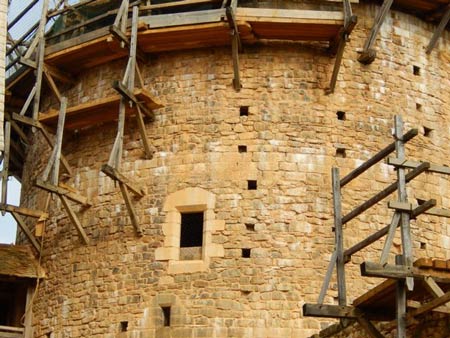

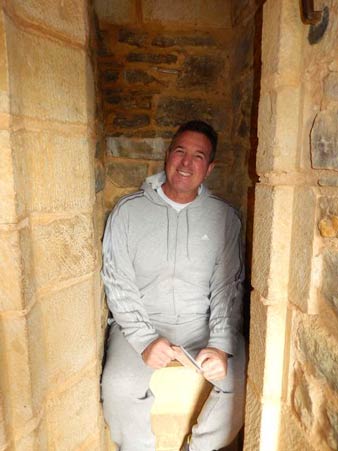

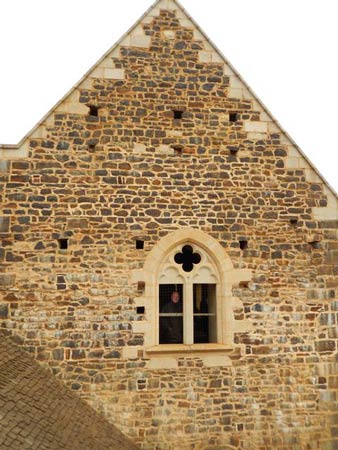

- Jim’s Photo Album

- Jim Weiss Responds to Parents’ Questions

- Testimonials

- Wholesale Information and ISBN’s

- Media and Review Inquiries

- Subscribe to the Jim Weiss Quarterly EMagazine AND/OR View Archives of Past EMagazine Blogs by Randy and Jim Weiss

- Contact Us

Jim Weiss Perfoms

Recordings

- A Quick Look at Jim Weiss Recordings by Title & Suggested Age Level

- The Newest Jim Weiss Recordings

- Recordings Currently Available From Well-Trained Mind Press

- Companion Readers/Dramatizations of Jim Weiss Recordings

- About Jim Weiss G.A. Henty Titles

- Jim Weiss’s Work for Other Publishers

- Servant God

Timeline & Subject Groups

More About Jim Weiss

Jim Weiss eMagazine